Now Reading: Comparison of IBIS and NBIS

-

01

Comparison of IBIS and NBIS

Comparison of IBIS and NBIS

INTRODUCTION

Forensic ballistics is a branch which involves the identification, individualization, evaluation and analysis of firearm evidences such as firearms, cartridge cases, bullets, GSR, firing pin marks, striation marks, etc. When any projectile is fired from a firearm, the contact between them leaves marks on projectile i.e barrel leaves distinct markings on bullet and cartridge case. The other markings are produces by firing pin, extractor and ejector. Each firearm leaves unique, random, microscopic irregularities or marks on the projectile that has been fired from it. Due to their uniqueness, these marks can be called as “ballistic fingerprint” and can be used to identify or eliminate the weapon. If the bullet and cartridge case is recovered by investigator from the crime scene and sent to the forensic lab for analysis, then the forensic ballistics expert can test-fire from suspect’s gun and can compare these marks obtained from test-fired bullet (controlled sample) with the marks obtained from crime scene bullet (questioned sample) to determine if that bullet was ejected from the same firearm. Similar is the procedure for cartridge cases.

HISTORY OF BALLISTICS IDENTIFICATION SYSTEM

In 1912, after examining the marks on barrel, Victor Balthazard concluded that these markings are unique to barrel and are imprinted as a series of striations on any projectile passing through that barrel. He also stated that it is possible to identify that a fired bullet originated from a barrel of a certain weapon and none other. The whole of modern firearm identification lies on the significance of Balthazard’s work. [1]

From centuries, the forensic ballistics experts have been comparing the bullets and cartridge cases using optical microscopes such as comparison microscope by visually examining the similarities and differences in the marks obtained on suspected and test-fired bullets or cartridge cases. In this process of visual examination, the stress on eyes of examiner lengthens the time of analysis and slows down the process. With advancement in digital technology, automated identification systems were introduced where technicians could automatically sort bullet’s and cartridge cases’ signatures. This resulted into speedy analysis of projectiles. Initially, the system was only capable of comparing bullets and was called “Bulletproof”. [1] Later, it was upgraded to examine cartridge cases and was renamed as “Integrated Ballistics Identification System (IBIS)”. [1] From 1993 to 1998, the United States had two automated ballistics identification systems- Drugfire under FBI (Federal Bureau of Investigation) and IBIS under ATF (Bureau of Alcohol, Tobacco and Firearms and Explosives). [2]

IBIS (INTEGRATED BALLISTICS IDENTIFICATION SYSTEM)

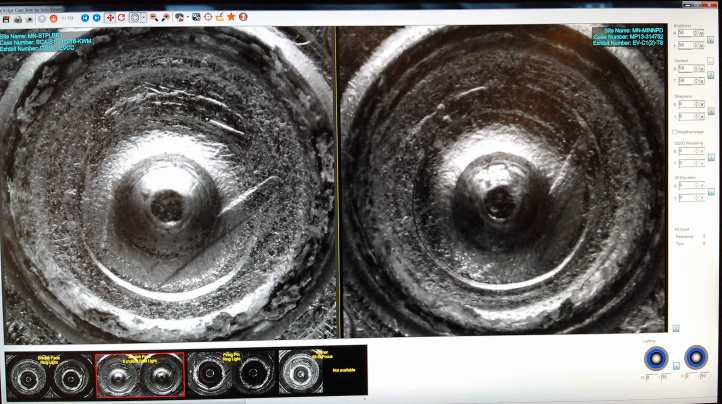

Integrated Ballistics Identification System (IBIS) is an automated software which produces, acquires, stores and compares the digital images of the markings made on projectiles- bullets, cartridge cases and shotshells seized from the crime scene as well as the test-fired ones. IBIS was developed by Forensic Technology Inc. and the program is controlled by ATF (Bureau of Alcohol, Tobacco and Firearms and Explosives). It has two modules- “Bulletproof” for bullets and “Brasscatcher” for cases. IBIS uses optical as well as electronic technology to digitally capture and compare the images of firing pin area of cartridge cases and marks on projectiles recovered from crime scene with the images that are already stored in the databases. The databases that store these images are NIBIN (National Integrated Ballistic Information Network) [3] database in United States of America and CIBIN (Canadian Integrated Ballistic Identification Network). [3] Sophisticated algorithms are used to compare the images using filters such as date of crime, date of entry, rifling specifications, caliber, etc. The IBIS operator may get a list of possible matches with the highest scoring correlation at the top. He may then compare the two images on monitor. If the association is confirmed, he may go for visual examination on comparison microscope.

There are two work stations of IBIS that operate independently:

- Data Acquisition Station (DAS): It photographs the surfaces of bullets and casings. It is used to collect image data. Laser optics focuses on the bullet’s land markings and computer digitally maps and records the significant areas on projectile’s surface.

- Image Analysis Station (Signature analysis Station-SAS): This station runs the image comparison program. As soon as the new image is entered, the system searches for a match by using advanced mathematical algorithms to correlate the new image with already stored images. It gives a list of scores relative to the possible matches (high or low). A single SAS can handle image data from many Acquisition Stations. [4]

Fig.1 Comparing Cartridge cases on IBIS TRAX [Source: http://artpictures.club/spring-may-7-11.html]

NIST BALLISTICS IDENTIFICATION SYSTEM (NBIS)

National Institute of Standards and Technology (NIST) has developed new identification techniques of 3D topography measurement on correlation cells called as NIST Ballistics Identification System (NBIS) [5] which includes development of Congruent Matching Cells (CMC) [5] method, etc. to enhance the accuracy and speed of firearm evidence identification. The striation marks on bullet are 2D profiles and the firing pin, breach face and ejector mark signatures are 3D topography images. In CMC (Congruent Matching Cells) method, the total surface area of 3D forensic image is divided into multiple correlation cells. This is done to determine valid and invalid correlation regions. Not whole of the surface area of bullet or cases possess the markings hence there is no need to compare the whole surface area. The cells containing the features which can be used for comparison are called valid correlation regions whereas invalid correlation regions are those which lack unique markings due to their less interaction with the firearm. The surface is divided into these two types of regions to maximize the similarity between valid regions by eliminating the invalid regions to speed the calculation.

Cells are called as congruently matching cells when:

- a high surface topography similarity is observed (it is quantified by ACCFmax – Area cross correlation function maximum) [6]

- similar registration angles (θ) are obtained for all correlation cells [6] [7]

- a congruent x-y spatial distribution pattern is obtained for the correlation cells [6] [7]

Fig.2 Schematic diagram of topographies A and B originating from the same firearm and registered at the position of maximum correlation. The six solid cells pairs are located in three valid correlated regions (A1, B1), (A2, B2), and (A3, B3). The three dotted cell pairs (a’, b’), (a”, b”), and (a’”, b’”) are located in invalid correlation region. [2] [8]

There is the concept of CMC number which is similar to the concept of CMS (Consecutive matching striae) developed by Biasotti and Murdock for identification of bullet striations. [8] A and B are called to be a match when CMC is equal to or greater than 6. Fig.2 shows that the topographies A and B have been originated from the same firearm.

COMPARISON OF IBIS AND NBIS

Large number of comparisons can be done using both the systems. The IBIS output is in the form of correlation score of possible matches hence the confirmation has to be given by the examiner after comparing the original materials under comparison microscope. On the other hand, NBIS gives quantitative correlation of geometrical topography as well as optical images for firearm identification. [9] CMC method speeds the identification by automatically eliminating the invalid correlation cells and focuses only on the valid cells of interest. CMC and its error rate estimation can assist in developing next generation ballistics identification systems. [9]

The following table shows the clear difference between the two systems.

|

IBIS |

NBIS |

| 1. IBIS stands for Integrated Ballistics Identification System. |

1. NBIS stands for NIST Ballistics Identification System. (NIST- National Institute of Standards and Technology) |

| 2. IBIS is considered as a commercial automated ballistics identification system. | 2. NBIS is the latest technique of ballistics identification. |

| 3. IBIS acquires 2D image of surface of bullets and cases. | 3. NBIS acquires 3D surface topographies of bullets and cases and can also examine damaged bullets as well as cartridge cases with complex shaped firing pin signatures. |

| 4. The result of IBIS is totally depended on the quality of image which might be affected by the lighting conditions such as lighting direction, color, intensity, contrast, reflectivity of material, light source, etc. [8] [9] [10] | 4. NBIS method can eliminate the errors occurring due to variable lighting conditions and shadowing. |

| 5. The parameters and algorithms used in IBIS are proprietary and are not available for open testing. This leads to the difficulty in laboratory assessments and inter-comparisons among different systems.

|

5. The parameters and algorithms used in this system are easy to use and are in public domain and are available for open testing. [8] [9] [10]This can make inter-comparison among different identification systems possible. |

| 6. IBIS compares the entered image with the images stored in NIBIN (National Integrated Ballistic Information Network) and CIBIN (Canadian Integrated Ballistics Information Network) databases. | 6. NBIS compares the surface topography of projectiles with the data stored in NIST Ballistics Toolmark Research Database (NBTRD). |

CONCLUSION

Both IBIS and NBIS are good methods for firearm identification but certain issues such as lighting conditions, inter-comparison among other systems, analysis of damaged projectile, etc. are found to be solved in the latter method. There are large number of ballistics identification systems. But it is strongly believed that these systems cannot replace the examination by comparison microscopes. These systems generate a list of possible matches and help ballistic expert to narrow down the samples for visual examination on comparison microscope. Hence even if the automated identification system is highly capable, it is the examiner who makes the final decision whether there is a match or not.

REFERENCES

- Heard, B. (2008) Forensic Firearms Examination. The Handbook of Firearms and Ballistics (pp.145-208), Wiley-Blackwell, John Wiley & Sons. Ltd Publication, 2008.

- Monturo, C. (2019) Emerging technology in comparisons. Forensic Firearm Examination (pp.275-304), Elsevier Science & Technology. DOI: https://doi.org/10.1016/B978-0-12-814539-5.00015-0

- CFS- Technical Information Sheets- Integrated Ballistics Identification System (May 2019) [Last accessed on- 04/05/2021]. Available from- https://www.mcscs.jus.gov.on.ca/english/centre_forensic/InformationforInvestigatorsSubmitters/TechnicalInformationSheets/FirearmsToolmarks/CFS_IBIS_tech.html

- Automated Firearms Ballistics Technology [Last accessed on- 04/05/2021]. Available from- https://www.atf.gov/firearms/automated-firearms-ballistics-technology

- Song, J. (2013), Proposed NIST Ballistics Identification System (NBIS) based on 3D Topography Measurements on Correlation Cells, Journal of Association of Firearm and Tool-mark Examiners, 45(2): 184-194. [Last accessed on- 04/05/2021]. Available from- https://www.nist.gov/publications/proposed-nist-ballistics-identification-system-nbis-based-3d-topography-measurements

- J. A. T. Mattijssen, Interpol review of forensic firearm examination 2016-2019. Forensic Science International: Synergy. DOI: https://doi.org/10.1016/j.fsisyn.2020.01.008

- Gheorghe, B. (May 2012) Automated Systems used in the Criminal Identification of Firearms. Scholarly Journal, 13(2): 342-347. [Last accessed on- 04/05/2021]. Available from- https://www.proquest.com/scholarly-journals/automated-systems-used-criminal-identification/docview/1082326859/se-2?accountid=201395

- Vorburger, T., Song, J., Petraco, N. (2016) Topography measurements and applications in ballistics and tool mark identifications Surface Topography: Metrology and Properties, Topical review. DOI: https://doi.org/10.1088/2051-672X/4/1/013002

- Song, J., Liu, X. (2015) A Review of NIST Projects in Surface and Topography Metrology for Firearm Evidence Identification in Forensic Science. Journal of Scientific and Industrial Metrology [Last accessed on- 04/05/2021]. Available from- https://metrology.imedpub.com/a-review-of-nist-projects-in-surface-andtopography-metrology-for-firearm-evidenceidentification-in-orensic-science.php?aid=8410

- Song, J., Chu, W., Vorburger, T., Thompson, R., Renegar, T., Zheng, A., Yen, J., Silver, R., and Ols, M. (2012) Development of Ballistics Identification- From Image Comparison to Topography Measurement in Surface Metrology. MeasSciTechnol 4:6. DOI- https://doi.org/10.1088/0957-0233/23/5/054010